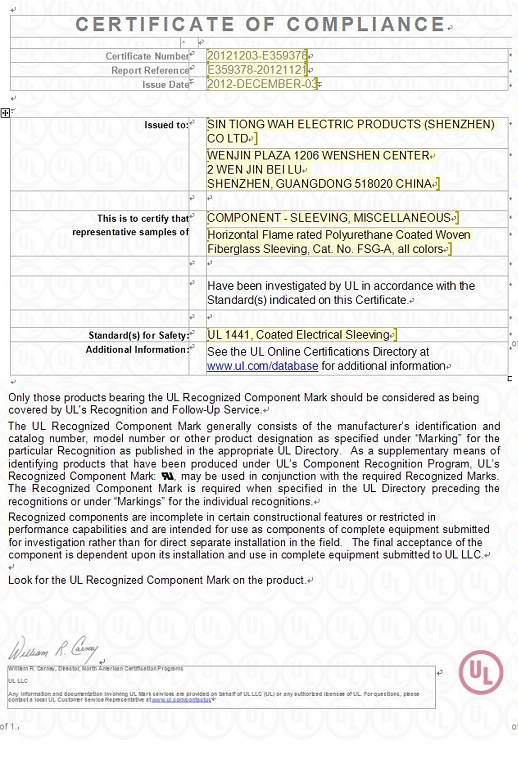

File E359378 Project 12SC02971 November 21, 2012

REPORT On COMPONENT ¨C SLEEVING, - MISCELLANEOUS

Sin Tiong Wah Electric Products (Shenzhen) Co. Ltd. Guangdong,

China

Copyright Ó 2012 UL-LLC

UL LLC authorizes the above

named company to reproduce this Report either in its entirety or

the portion of this Report consisting of the Cover Page up to

(but not including) the Construction Details descriptive pages.

File E359378 Vol. 1

Sec. 1 Page 1 Issued: 2012-11-21 and

Report

CRIPTION PRODUCT COVERED:

Component - Miscellaneous Sleeving: Horizontal Flame

rated Polyurethane Coated Woven Fiberglass Sleeving, Cat. No. FSG-A,

all colors

GENERAL DESCRIPTION OF MATERIAL (NOT FOR FIELD REPRESENTATIVE'S

USE):

The sleeving covered by this Report are made up of a woven

continuous filament of glass fiber and coated with polyurethane

polymer.

MARKING:

Full Recognized Company name or file number "E359378",

catalog Number designation, date of manufacturer (or a traceable

code) and factory ID (if required on Auth. Addendum page) on the

outside of the spool, on a separate tag on each end of the

sleeving, on the bundling wrapper or on the outside of the

smallest unit container in which the product is packaged.

TECHNICAL CONSIDERATIONS (NOT FOR FIELD REPRESENTATIVE'S USE):

Use - for use only on products where the acceptability of

the combination is determined by Underwriters Laboratories Inc.

1. The sleeving covered by this Report has been investigated for

flammability only and has been found to comply with the

Horizontal flame requirements. No other tests have been

performed.

2. Not for use were a VW-1 Flammability rating is required. The

sleeving complies with the Horizontal flame only in accordance

with the requirements in UL 1441

File E359378 Vol. 1 Sec. 1 Page 2

Issued: 2012-11-21 and

Report

CONSTRUCTION DETAILS:

The sleevings are constructed of continuous woven filament

glass fiber and are produced in the following sizes having

coating impregnation as specified.

|

Cat. No. |

Sleeving Overall

Color |

Coating / Colors |

Mfg. / Grade |

Glass Braid |

|

FSG-A |

All Colors

|

Polyurethane /

All Colors and Clear

(natural) |

Self-made, Sin Tiong

Wah Electric Products (Shenzhen) Co. Ltd. / ¡°AP-51¡± |

Tightly Woven White

Fiberglass |

Note: White fiberglass

sleeving with clear coating appears as a white sleeving

Dimensions - The sleeving

shall conform to the following Table.

|

Cat. No. |

Sleeving Overall Color |

Nominal Inside Diameter, mm |

Inside Diameter Range, mm |

Total Wall Thickness Range,

Minimum Any Point to Maximum,

mm |

|

FSG-A |

All Colors |

1.0 |

0.8-1.2 |

0.50-0.60 |

|

1.5 |

1.3-1.7 |

0.50-0.60 |

|

2.0 |

1.8-2.2 |

0.50-0.62 |

|

2.5 |

2.3-2.7 |

0.50-0.62 |

|

3.0 |

2.75-3.25 |

0.50-0.62 |

|

3.5 |

3.25-3.75 |

0.50-0.62 |

|

4.0 |

3.75-4.25 |

0.50-0.62 |

|

5.0 |

4.75-5.25 |

0.50-0.62 |

|

6.0 |

5.75-6.25 |

0.50-0.62 |

|

7.0 |

6.75-7.25 |

0.50-0.62 |

|

8.0 |

7.7-8.3 |

0.70-0.85 |

|

9.0 |

8.7-9.3 |

0.70-0.85 |

|

10.0 |

9.7-10.3 |

0.70-0.85 |

|

12.0 |

11.7-12.3 |

0.70-0.92 |

|

14.0 |

13.5-14.5 |

0.70-0.95 |

|

16.0 |

15.5-16.5 |

0.70-0.95 |

|

18.0 |

17.5-18.5 |

0.70-0.95 |

|

20.0 |

19.5-20.5 |

0.70-0.95 |

|

25.0 |

24.4-25.6 |

1.0-1.3 |

|

30.0 |

29.4-30.6 |

1.2-1.4 |

Sizes between two given sizes

shall comply with the larger size.

¡¡